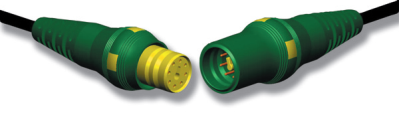

Looking for moisture resistant connectors that also withstand harsh environmental hazards such as water…dirt…chemicals…hospital fluids…salt? Looking for easy push-pull connections, fast mate and de-mate cycles with no moving parts or tools required?

Tuff-Seal handles your requirements with ease. Whitney Blake’s patented Tuff-Seal connectors:

- Meet IP68 requirements.

- Enable easy, faster mate and de-mate with high cycle counts and without compromising the sealing capabilities.

- Protect internal contacts from moisture and environmental hazards with a full seal.

- Offer protection against immersion in water at depths greater than 3 meters for long periods of time.

- Are highly flexible and retractable.

- Resist exposure to chemicals.

- Are suitable for any application where harsh environments are a factor.

Like all Whitney Blake cables, cords, connectors and harnesses, Tuff-Seal connectors and cable systems are:

- Customizable: For example, we can customize the mating/de-mating force to meet your specific application requirements.

- Safe: The easy mate and passive latching features keep operators and equipment safe. There are no exposed conductive surfaces to cause electrical shorts. The ease with which the Tuff-Seal connectors will de-mate prevents operators or test equipment from being pulled into moving parts.

- Easy to use: Alignment keys and/or customized connector shapes and pinouts make mating easy and efficient, while preventing electrical cross-over.

- Adaptable: Tuff-Seal connector systems can be designed to meet your specifications for both cable and panel mount.

When you need extraordinary performance, call on Whitney Blake.

Learn more about Tuff-Seal in action by reading our Case Study and information about Marine Applications.

Moisture resistant cables that protect against immersion in water at depths greater than 3 meters for long periods of time.

Moisture Seal:

- Fully sealed, meets IP68 requirements

- Protects internal contacts from exposure to moisture, dirt, chemicals, salt & environmental hazards

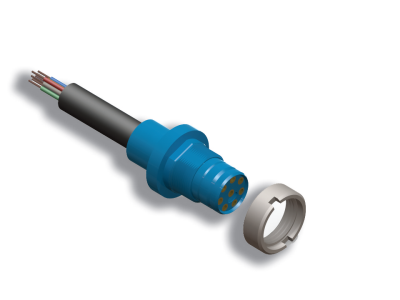

Passive Latch:

- Mating / de-mating force may be customized to meet specific application requirements

- Passive latch minimizes OEM equipment damage should cable snags occur

- Quick disconnect

- Acts as safety feature so operators and/or test equipment do not get pulled into moving parts

- No exposed conductive surfaces while mated to cause electrical shorts

- Alignment keys for easy mating & protection from electrical cross over

- Available in both cable & panel mount

- No moving parts in connector, eliminating risk of jamming

Panel Mount

Cable Mount